Since 2009 we've been making our products in the US, but the reasons for that have evolved- as have the processes we use.

In the beginning, producing things locally was the most direct path to bringing my ideas to life. Eventually, our products became more complicated and more costly to produce. But keeping production close by allowed me to develop products directly with the sewing company- streamlining the design and production process.

More than that, I found that I enjoyed the process of working directly with the sewers. Understanding the construction contributed to making better products, as well as my fulfillment from the experience.

As we began to grow, I did explore making products in other countries- even visiting several factories. This was partly because we were approaching the capacity of our local sewers, but also because some factories have additional capabilities enabled by high tech equipment. But I found that most of the processes were more manual than I would have thought, and the skill range of the sewers varies widely. One team may sew the samples you receive, but a different group will sew the production pieces.

This introduces two problems: QA and waste. Once sewing is complete, they need to be thoroughly inspected. Items that don't pass are usually discarded. For most products, the economics of this works. But because our material is so expensive, it's much better to have sewers QA themselves along the way at each step. With our current process the reject rate is incredibly low.

After talking to many others who had gone down that path, it didn't feel like a good fit for me. It requires a lot of time making samples, documenting designs, and checking quality. I wanted to find ways to condense the gap between sketch and production, and outsourcing felt like it would create a larger gap, not close it.

When I got my own studio in 2019 it was meant to be a way for me to fully prototype things myself using industrial equipment. So moving things into production became less of a translation and more of a seamless transition.

Once I got a laser cutter, I could start to see a potential path open up where we could produce at least some of our own products. A subsequent visit to the Juki HQ in Japan opened my eyes to some advances in sewing technology and the puzzle pieces started coming together.

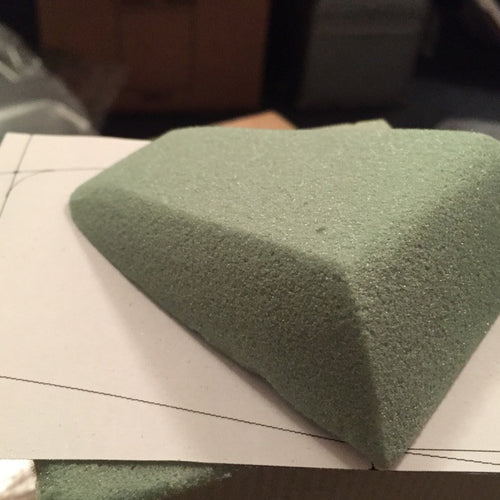

Now our in-house production is essentially scaled up prototyping, using more precise methods than what would typically be found in factories. Our in-house production can either supplement the volume of the local production partner or produce the initial production runs while things are still being refined. It also sets us up to be able to do smaller runs of special editions or collaborations. Our first one is the special edition Kickstarter green for the Global Wallet.

While a lot of the world has been shifting their global supply chain in response to tariffs or other costs, we've been evolving our process to make the best possible product. And so far, that path has led us closer and closer to home.

Great to hear more about the journey, technology, etc… my two year old micro tyvek is still going strong. A great product that I get plenty of postive commentary on, keep going!

Nice article. I have bought 2 wallets one was several years back still going strong. One was recent. My hope is products and industry can find a way back to U.S.A.

Congratulations on your ongoing success. Proves that legwork and face to face is more effective than sitting in front of a computer and FaceTiming. Now if only the Canadian vs US dollar exchange rate would be more favourable.

Thanks for reading and glad you liked it Ronald!

Great article Dave! Thanks for sharing your Made in the USA story!