This has been a unique and challenging year all around and it's the first time I’ve had a Kickstarter finish up just ahead of the holidays. It’s been quite a push to get all of the packages out and I’m happy to say I’ve managed to continue to make progress on the Sling Pack production as well. Here’s a rundown of where we’re at…

Pre-orders now open

First of all, if you missed out on the Kickstarter, you can still pre-order it here:

If you’re already a backer and decide you want another one, it’s probably best to wait for the survey and add one on there.

Materials

In the risks and challenges section of Kickstarter, I identified procurement as the biggest risk to the timeline. These days it seems hard to get anything in a timely manner so I wanted to build in some time just in case some of the things I needed were on backorder. I had most of the items on hand but the biggest ones I wasn’t sure about were the specialized rubber for the base, sliders for the zippers, and elastic for the pockets.

Fortunately the rubber base material turned out to be no problem at all- just heavy and expensive to ship! The sliders were initially going to take 4-6 weeks to get but YKK found ONE BOX of exactly the ones I needed. Fun fact- you need to buy 4,000 sliders at a time if you want to get the specialized kind I like.

Last was the elastic and… unfortunately the manufacturer discontinued it. A friend put me in touch with a Japanese supplier Shindo who carries 42,000 different roll products and they had a great alternative. The price was almost double but I thought I’d go for it. Then… it also turned out it was shipping from Japan and the shipping and duties was the same cost as the product cost! So basically it’s 4x the price. I really like the stuff and it keeps production moving so I went ahead and ordered it and it arrived in just 2 days from Japan.

These kinds of things are very common during the course of producing a product. Even if you know exactly what you want, things may turn out to be more expensive than you originally budgeted. In a way, backers benefit from this because I’ve already committed to the price, but having paid for the product up-front balances things out and allows me to order the right amount of material. So it’s really a balancing act where I get to a point of reasonable certainty about my ability to get all the materials and then take a chance that everything will pencil out in the end.

Production

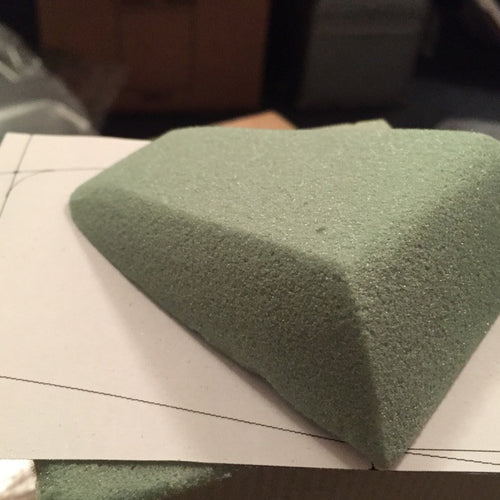

With all of the materials in hand, we’ve reached an important milestone. Purchase orders have been submitted to the factory in San Francisco and fabric cutting has begun.

Once they produce the first couple of bags, they’ll pause production for me to review them. This is known in the apparel industry as inspecting “tops”- the items on the top of the pile as the production line starts up. This is done because even if the sample was good, it may not be made in exactly the same way as full production… different sewers, different steps, etc. So it’s just one more quality check to make sure the bags are made right.

Survey

For the survey, I’ll be using software called Crowd Ox which is similar to BackerKit. In fact, BackerKit bought Crowd Ox during my campaign so they may soon be the same!

I’ve got to set that up so you’ll be able to choose add-ons and all that good stuff so keep an eye out for that in January. The plan is for that to be the topic for our next update.

Until then, have a safe and wonderful holiday!

@Christopher – Surveys just went out so you can check your inbox. Thanks!

so when are we going to get our surveys?