- Named New York Times Wirecutter #1 Top Pick 2023.

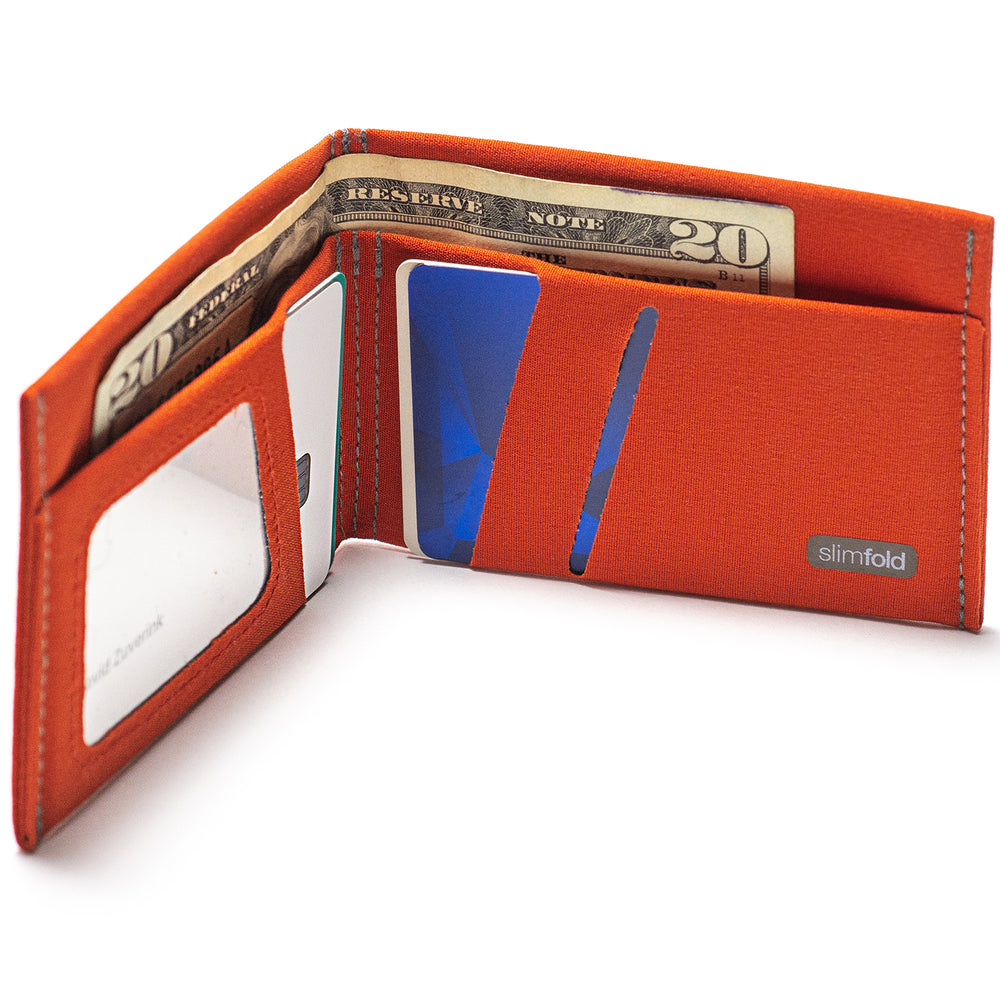

- Holds up to 11 credit cards and cash.

- Keeps contents organized with bill pocket tall enough for US currency and card slots.

- 2-3 times thinner than leather by using advanced materials and construction techniques.

- Stays looking new for years.

- Backed by our 5 year warranty.

Our best seller- one of the most versatile wallets we make. It's a great balance between a small footprint and fully functional men's wallet.